Product Description:

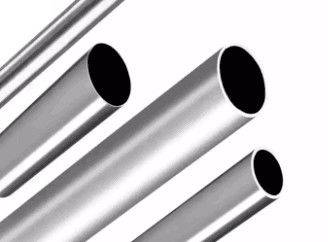

An Alloy Steel Tube is a versatile and durable product used in various industries for its strength and corrosion resistance properties. This particular Alloy Steel Tube is designed with specific attributes to cater to the needs of applications such as oil, gas, and fertilizer industries.

The ends of this Alloy Steel Tube come in three variations to suit different installation requirements: Plain, Beveled, and Threaded. The Plain Ends offer a simple and smooth finish, ideal for applications that do not require any additional features. The Beveled Ends are designed with a sloping edge for easy welding and alignment, providing a secure and leak-proof connection. The Threaded Ends are threaded to allow for easy installation and removal, making them suitable for applications that require frequent assembly and disassembly.

This Alloy Steel Tube is produced using the Cold Drawn method, which involves pulling the steel through a die to achieve the desired dimensions and mechanical properties. Cold drawing results in a smooth surface finish and tight dimensional tolerances, ensuring the quality and consistency of the tube.

One of the key applications of this Alloy Steel Tube is in the transportation of fluids such as oil, gas, and fertilizer. Its high strength and corrosion resistance make it an ideal choice for demanding environments where reliability and performance are crucial. Whether used in pipelines, refineries, or chemical plants, this Alloy Steel Tube provides the durability and longevity required for critical applications.

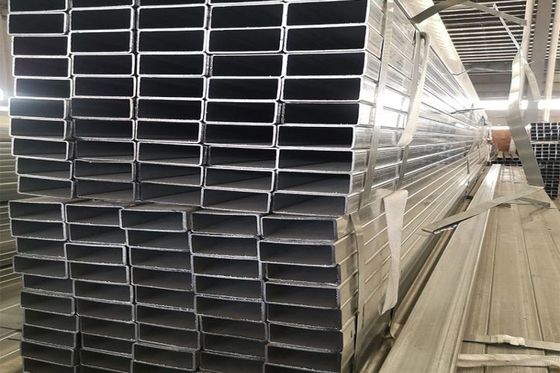

In addition to the various end options, this Alloy Steel Tube is available with two edge types: Mill Edge and Slit Edge. The Mill Edge is the standard edge condition, providing a clean and straight edge suitable for most applications. The Slit Edge is created by cutting the steel coil along its width, resulting in a slightly rounded edge that is ideal for applications where safety and handling are a concern.

Overall, this Alloy Steel Tube is a reliable and versatile product that meets the stringent requirements of the oil, gas, and fertilizer industries. With its multiple end and edge options, as well as its Cold Drawn production method, this Alloy Steel Tube is well-suited for a wide range of applications, including as an Alloy Steel Pressure Tube, Alloy Steel Line Pipe, and more.

Features:

- Product Name: Alloy Steel Tube

- Edge: Mill Edge Slit Edge

- Third Party Inspection: BV, SGS, ASP

- Width: 20mm-1800mm

- Production: Cold Drawn

- Length: Customized

Technical Parameters:

| Marking |

As Required |

| Surface |

Anodized,Brushed,Mill Finished,Polished |

| End |

Plain Ends / Beveled Ends |

| Width |

20mm-1800mm |

| Third Party Inspection |

BV,SGS,ASP |

| Color |

Bright,shinny |

| Ends |

Plain, Beveled, Threaded |

| Application |

Oil/Gas/Fertilizer |

| Advantage |

Strong Corrosion-proof |

| Length |

Customized |

Applications:

Product Application Occasions and Scenarios for JOHO Alloy Steel Tube:

JOHO Alloy Steel Tube, including Alloy Steel Line Pipe, Alloy Steel Seamless Tube, and Alloy Steel Pipe, is a versatile product suitable for various industries and applications.

Construction Industry: The Alloy Steel Tube can be used in construction projects for structural support, scaffolding, and framework due to its strength and corrosion-proof properties.

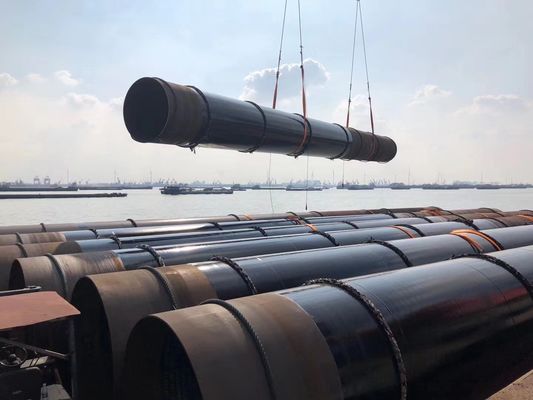

Oil and Gas Industry: JOHO Alloy Steel Tube is an ideal choice for oil and gas pipelines and drilling operations, providing durability and reliability under harsh conditions.

Automotive Industry: The Alloy Steel Tube is commonly used in the manufacturing of automotive parts and components, ensuring high performance and longevity.

Machinery Manufacturing: With its cold-drawn production process, the Alloy Steel Tube is perfect for machinery manufacturing, offering precise dimensions and superior quality.

Marine Industry: The strong corrosion-proof advantage of the Alloy Steel Tube makes it a preferred material for marine applications such as shipbuilding and offshore structures.

Infrastructure Projects: JOHO Alloy Steel Tube is essential for infrastructure projects like bridges, tunnels, and railways, where reliability and longevity are crucial.

Energy Sector: Whether for power plants or renewable energy projects, the Alloy Steel Tube meets the high standards required in the energy sector.

Manufacturing Sector: Various manufacturing processes benefit from the Alloy Steel Tube, thanks to its mill edge slit edge and surface options like anodized, brushed, mill finished, and polished.

Supply Chain and Distribution: JOHO Alloy Steel Tube, with its ISO 9001 certification and flexible payment terms, is trusted by businesses worldwide, ensuring timely delivery within 40 days and a minimum order quantity of 1 ton.

Packaging and Handling: Each Alloy Steel Tube is carefully packaged in woodencase or woven bag, with marking as required, reflecting the quality and attention to detail of the JOHO brand from CHINA.

Customization:

Product Customization Services for Alloy Steel Tube:

- Brand Name: JOHO

- Place of Origin: CHINA

- Certification: ISO 9001

- Minimum Order Quantity: 1 TON

- Packaging Details: Woodencase/Woven bag

- Delivery Time: within 40 days

- Payment Terms: LC,TT,ect,.

- Colour: Bright,shinny

- Production: Cold Drawn

- Marking: As Required.

- Width: 20mm-1800mm

- Ends: Plain, Beveled, Threaded

Keywords: Alloy Steel Heat Exchanger Tube, Alloy Steel Pipe, Alloy Steel Boiler Tube

Support and Services:

Our Product Technical Support team for Alloy Steel Tube is dedicated to assisting customers with any technical inquiries or issues they may encounter. Our knowledgeable experts are available to provide guidance on product specifications, applications, and troubleshooting.

In addition to technical support, we offer a range of services for our Alloy Steel Tube product, including installation assistance, maintenance recommendations, and product training. Our goal is to ensure that customers have a positive experience using our Alloy Steel Tube and are able to maximize its performance and longevity.

Packing and Shipping:

Product Packaging:

The Alloy Steel Tube is carefully packaged in protective material to prevent any damage during transportation. It is then sealed in a sturdy cardboard box to ensure its safety during shipping.

Shipping:

Once the Alloy Steel Tube is packaged, it is placed in a shipping container and labeled with the necessary information such as the destination address and tracking number. It is then ready to be shipped via the selected shipping method.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!