Product Description:

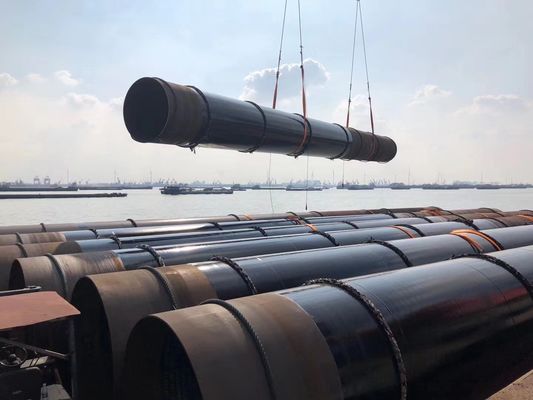

The Alloy Steel Tube is a vital component of any Alloy Steel Tubular System, known for its exceptional strength and corrosion resistance. This Alloy Steel Seamless Tube is designed to withstand harsh environments and demanding applications, making it ideal for use in industries such as oil, gas, and fertilizer.

One of the key advantages of this Alloy Steel Tube is its strong corrosion-proof properties, ensuring long-term durability and reliability even in corrosive conditions. This makes it a preferred choice for critical applications where resistance to corrosion is paramount.

The Alloy Steel Tube is available with different types of ends to suit various installation requirements. The ends can be Plain, Beveled, or Threaded, providing versatility and ease of connection in different configurations.

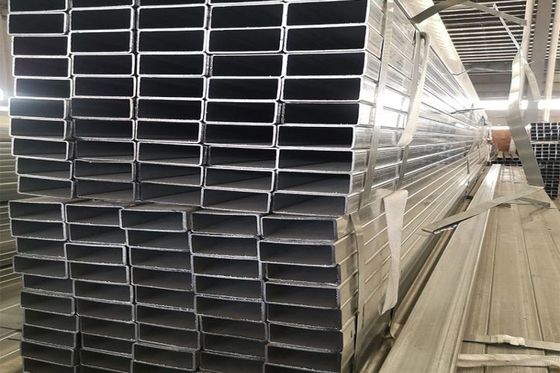

With a width ranging from 20mm to 1800mm, this Alloy Steel Tube offers flexibility in terms of sizing, allowing for customized solutions to meet specific project needs. The wide range of widths ensures compatibility with a variety of piping systems and structural designs.

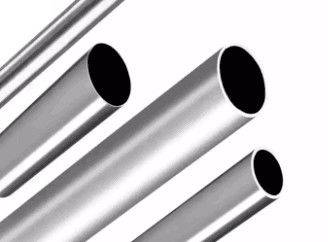

When it comes to surface finishes, the Alloy Steel Tube can be Anodized, Brushed, Mill Finished, or Polished, providing options for different aesthetic preferences and functional requirements. The surface finish not only enhances the appearance of the tube but also helps protect it from environmental factors.

Overall, the Alloy Steel Tube is a versatile and durable product that excels in demanding environments and applications. Its strong corrosion-proof properties, variety of end types, wide range of widths, and surface finish options make it a reliable choice for a wide range of industries, including oil, gas, and fertilizer.

Features:

- Product Name: Alloy Steel Tube

- Marking: As Required

- Production: Cold Drawn

- Width: 20mm-1800mm

- Ends: Plain, Beveled, Threaded

- Technique: Hot Rolled, Cold Drawn

Technical Parameters:

| Attribute |

Options |

| Ends |

Plain, Beveled, Threaded |

| Third Party Inspection |

BV, SGS, ASP |

| Technique |

Hot Rolled, Cold Drawn |

| Surface |

Anodized, Brushed, Mill Finished, Polished |

| Marking |

As Required |

| Length |

Customized |

| Width |

20mm-1800mm |

| Edge |

Mill Edge, Slit Edge |

| Production |

Cold Drawn |

| Advantage |

Strong Corrosion-proof |

Applications:

JOHO Alloy Steel Tube is a versatile product that finds application in a wide range of scenarios due to its exceptional attributes. Crafted in CHINA, this product boasts ISO 9001 certification, ensuring high quality and reliability. The minimum order quantity of 1 TON makes it accessible for various needs.

One of the key application occasions for the JOHO Alloy Steel Tube is in the construction of Alloy Steel Tubular Systems. The durable and sturdy nature of this product makes it ideal for creating robust structures that require strength and resilience. Whether it's for industrial complexes, bridges, or pipelines, the JOHO Alloy Steel Tube is a trusted choice.

Another common scenario where the JOHO Alloy Steel Tube excels is in the manufacturing of Alloy Steel Cylinders. The product's bright and shiny color, achieved through the Hot Rolled and Cold Drawn production techniques, adds a touch of sophistication to the cylinders. Whether used in hydraulic systems, machinery components, or pressure vessels, the JOHO Alloy Steel Tube delivers on both form and function.

Furthermore, the customization option for length allows for tailored solutions in various projects. The packaging details in woodencase or woven bag ensure safe transportation, while the delivery time of within 40 days guarantees timely fulfillment of orders. Flexible payment terms such as LC, TT, etc., cater to different preferences, making the purchasing process smooth and convenient.

In addition, the JOHO Alloy Steel Tube can be marked as required, adding a personal touch or specific identification for different applications. With its cold drawn production technique, this product meets diverse needs across industries, making it a go-to choice for Alloy Steel Tubular Systems and Alloy Steel Cylinders.

Customization:

Product Customization Services for Alloy Steel Tube:

Brand Name: JOHO

Place of Origin: CHINA

Certification: ISO 9001

Minimum Order Quantity: 1 TON

Packaging Details: Woodencase/Woven bag

Delivery Time: within 40 days

Payment Terms: LC, TT, etc.

Application: Oil/Gas/Fertilizer

Third Party Inspection: BV, SGS, ASP

Ends: Plain, Beveled, Threaded

Technique: Hot Rolled, Cold Drawn

Length: Customized

Support and Services:

Our Product Technical Support and Services for Alloy Steel Tube include:

- Expert assistance with product specifications and selection

- Guidance on installation and usage of Alloy Steel Tube

- Troubleshooting support for any technical issues

- Training programs on handling and maintenance of Alloy Steel Tube

- Regular updates on product enhancements and improvements

Packing and Shipping:

Product Packaging:

The Alloy Steel Tubes are carefully wrapped in protective material to prevent any damage during transit. Each tube is then placed in a sturdy cardboard box with ample cushioning to ensure safe delivery.

Shipping Information:

We offer fast and reliable shipping services for our Alloy Steel Tubes. Orders are processed promptly and shipped via trusted carriers to ensure timely delivery to your location. Tracking information will be provided so you can monitor the status of your shipment.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!